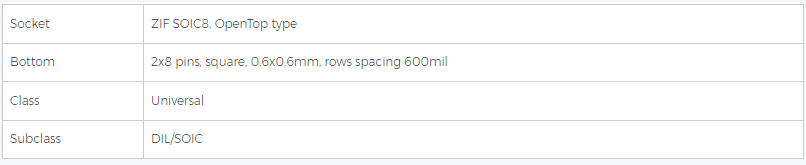

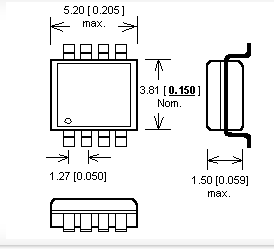

Universal Adapter SOIC8SP is assigned for devices in SOIC8/SOP8/VOIC8 package (for example serial EEPROMs, serial FLASHs, Zilog Z8Fxxxx series, Atmel ATtiny series, STM ST7xxx series, Microchip PIC 12xxx series).

Insert adapter to the device programmer ZIF socket according to the picture placed near of it. If you have some doubts about orientation of this adapter in device programmer ZIF socket, it is valid general rule, the orientation of the text of title is the same as the text on the top of the device programmer.

Push the top of adapter ZIF socket to open it. Insert the device into the adapter ZIF socket. The right position of the programmed device in adapter ZIF socket is show at picture near (mainly left above) the adapter ZIF socket. Then release adapter ZIF socket.

Visually check interconnection between device and adapter ZIF socket. If everything looks OK, the device is ready for programming.

Be careful, because the incorrect insertion of adapter to the device programmer ZIF socket or device to the adapter ZIF socket can damage the programmed device.

To take out the device push the top of adapter ZIF socket and remove device from it.

When you finish work with adapter, remove it from the device programmer ZIF socket.

Do not directly touch the pins of the adapter and adapter ZIF socket, because dirt may cause errors during programming of device.

For handling with the device we recommended to use a vacuum pick up tool.

Operation conditions: operating temperature 5°C ÷ 40°C (41°F ÷ 104°F), operating humidity 20%..80%, non condensing.

If programming yields isn't 100% when using programming adapter or if some unreliability appears, try to connect one 22nF-100nF multilayer capacitor (that meet the EIA X7R or Z5U specification) between leads of adapter connected to pins VCC and GND pins of programmed chip.

Functions:

(1) Incoming material inspection

The chip needs to be inspected for quality before use in order to eliminate defective products and improve the SMT yield rate. The quality of the chip can not be seen by the naked eye alone, must be detected by powering up, with the common method of detecting IC current, voltage, inductance, resistance, capacitance can not fully judge the IC good or bad, must be applied through the test socket function to run the program to accurately determine.

(2) Rework detection

Through the test block can save maintenance judgment analysis time to eliminate the causes of bad, reduce the number of motherboard back to solder to reduce the risk of scrap repair board. In addition, the IC in the process of disassembly may be damaged, using the test station can be quickly bad IC sub-check out, the test OK IC reuse to reduce the cost of maintenance collaterals, especially for the unit price of high IC is more applicable.

(3) Burn-in/programming

IC test adapters are installed on the printed circuit board to form IC burn-in holders/IC programming holders/IC adapters, which can be used to program and burn-in ICs or modules by connecting to the appropriate burner.

(4) Ageing test

Component failure mainly occurs at the beginning and the last tenth of the life cycle, aging is through the working environment and electrical performance of the components of the two aspects of the harsh test, speed up the work of the components in the first 10% of its life, and make the defects in the short term, as far as possible to make early detection of failure.

Fields of application:

Cost analysis:

Cost mainly depends on the number of pins, pitch (Pitch), frequency, test requirements (such as temperature, current, life, heat dissipation, etc.) of the IC or module under test, the higher the number of pins, the higher the frequency, the higher the test requirements will increase the cost of the corresponding probe; the higher the number of pins, the smaller the pitch will increase the difficulty of processing the aperture plate and enhance the processing scrap rate, thus affecting the overall price.

Test sockets structure:

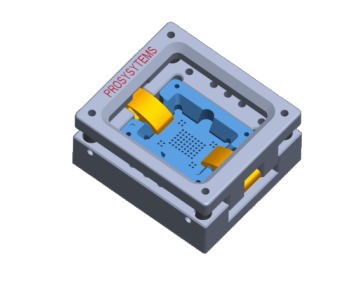

Bounce type: suitable for automatic machine testing of chips or modules, programming, etc., also can be manually pressed or pressed with a booster jig.

Example.

Alloy top window type test holders

Product features:

▪ Easy to operate, with automatic machine to reduce labour intensity

▪ The special head shape of the POGO PIN pierces the oxidation layer of the solder balls and provides reliable contact without damaging the balls.

▪ The floating plate structure makes it possible to measure ICs with and without balls.

▪ High precision positioning slots and guide holes ensure accurate positioning of the IC or module and high test accuracy

▪ The probe is replaceable, easy to disassemble, cost effective and the metal holder head can be recycled.

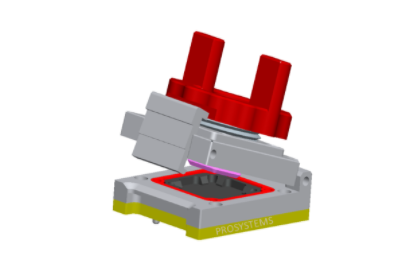

Flip-top type: suitable for manual testing of chips or modules, programming, etc.

Example.

Flip-top screw-on test holders

Product features:

▪ Manual flip-top screw-on construction, easy to operate, can be used for chips with a large number of pins

▪ Heat sink or cooling fan can be added to perform long programming tests according to requirements

▪ Floating top cover pressure block with automatic adjustment of the lower pressure to ensure even force on the IC or module

▪ The special head shape of the POGO PIN pierces the oxide layer of the solder balls and provides reliable contact without damaging them

▪ Floating plate structure for ICs with and without balls

▪High precision positioning slots and guide holes ensure accurate positioning of ICs and high testing accuracy

▪The probe is replaceable, easy to disassemble, cost effective, and the metal head can be recycled.

Test Adapter structure material:

Orifice plate, floating plate is the core component of SOCKET, play a fixed probe, guide the role of the chip, limit frame after a large number of tests may appear wear, thus leading to test instability, so there are high requirements for the material, currently on the market commonly used materials are PEEK, ceramic, Torlon, PEI, PPS, FR4, etc., of which FR4 is a common material, the cost is relatively low, easy to FR4 is a common material, relatively low cost, easy to wear, more burrs after processing, is now slowly being replaced.

Probe construction and use:

The probes are normally made of glassy copper with a gold plated outer layer and consist of four parts: the tip, the barrel, the tail and the slingshot;

The mechanical life of a probe is not equivalent to the actual life of the probe, as mechanical tests are carried out using a single probe in a laboratory environment, using vertical downward pressure. In practice, dozens or hundreds of probes are often used at the same time. Because of the precision of the machining of the parts, it is not possible to guarantee that each probe is equal and vertical after installation, and the load on the probes is not always the same, resulting in some probes being damaged prematurely, thus affecting the test life; in addition, the actual application environment often wears out the needles due to dust, chip dross, etc., but the Socket can be extended by replacing the probes However, the life of the socket can be extended by replacing the probe.

Only fully functional probes are capable of reliable signal transmission. The prerequisites for a good quality contact connection are.

▪ accurate probe position

▪no dirt or heavy wear on the tip of the needle

▪no grinding marks on the probe piston

▪no height differences between probes of the same type

▪no bending of the probe

Precautions for the use of the test adapter:

After a period of use, the test adapter may have some residual tin dross and dust at the tip of the needle. If the contamination is serious or contact is difficult, the probe can be cleaned with an anti-static brush or a precision electronic cleaner and the dirt particles scattered inside the test holder can be blown out with an air gun. Large radial forces may cause the probe to bend, do not apply shearing force on the probe when cleaning, do not use corrosive cleaning agents (e.g. Tiana water, board washing water, etc.), otherwise it will bring serious damage to the probe, or even scrap.

When the test stand is not used for a long time, it should be sealed in an anti-static bag and placed in a dry environment to prevent oxidation caused by the storage environment, resulting in poor contact. When using again, the probe should be observed for dirt or oxidation (black), if this phenomenon, please clean or replace the probe before use.