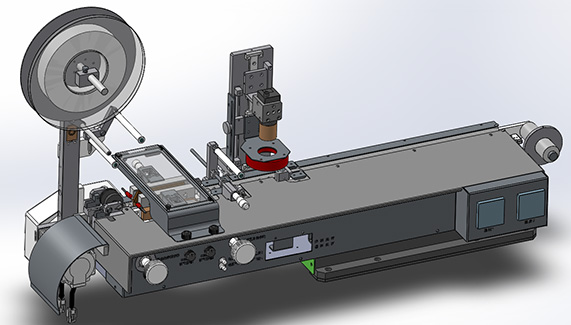

DPT500H is an online general-purpose module /PCBA product launched by our company-- a special equipment for converting tray packaging into tape packaging. The equipment can be directly connected with the SMT line to form a one-stop shipping system of sub-board, taping and packaging after AOI detection.

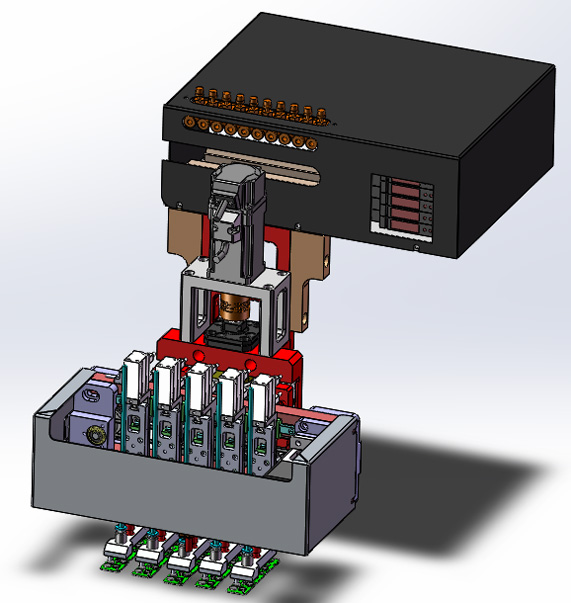

The equipment adopts 5 independent vacuum nozzles and variable spacing technology, which greatly improves the efficiency of chip pick and place. The capacity of DPT500A is up to 2500-4500PCS/H.

Application

Semiconductor: IC, Bluetooth, WiFi module, PCBA

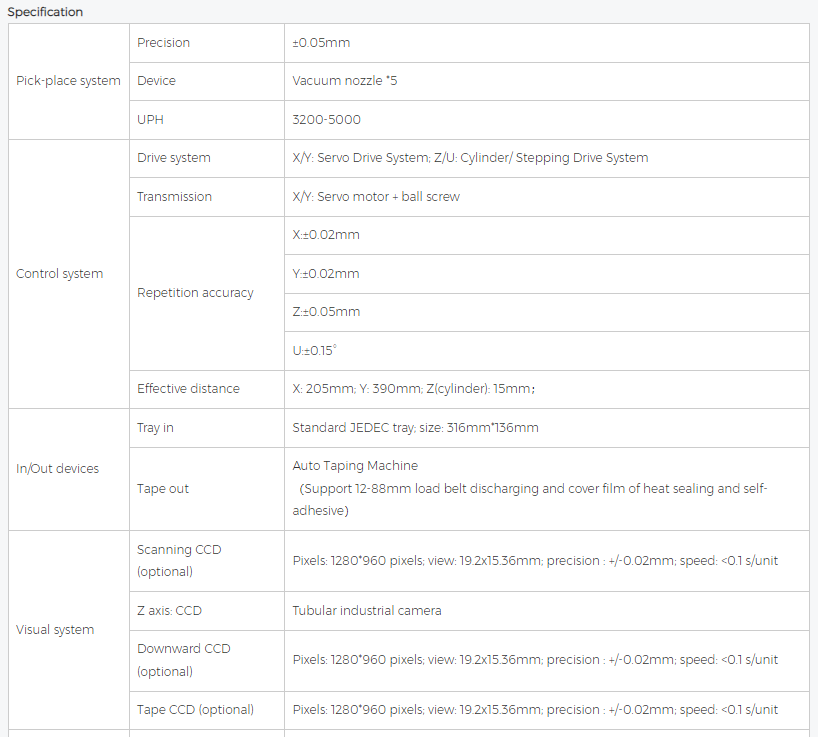

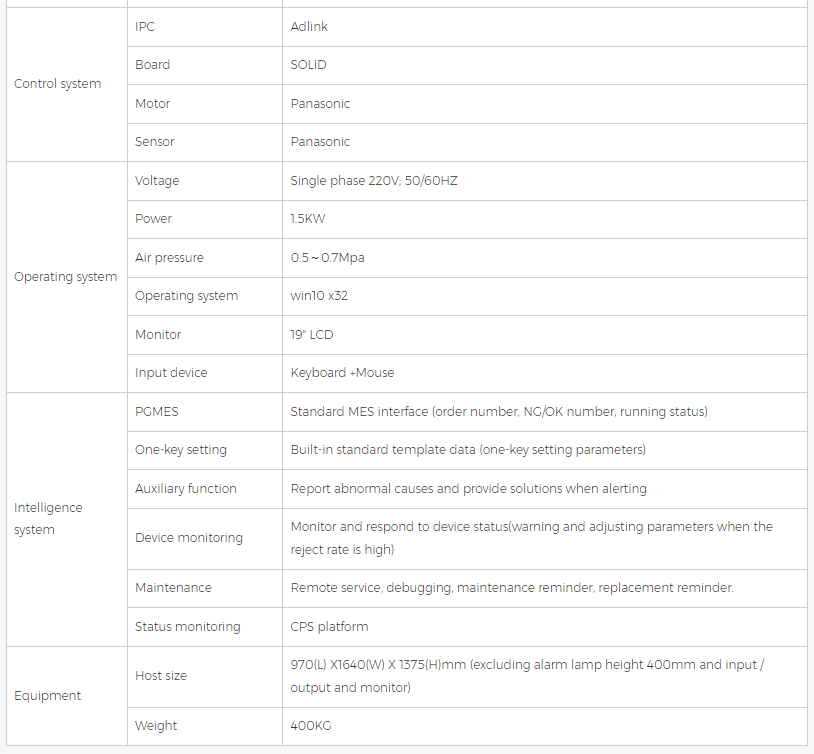

Specification

Tape width: 32-104mm

IC: 7*7 to 20*85

TRAY: 375mm(L)×400mm(W)*5mm(H); Customizable

Advanced function

Feeding in bulk, alarm for empty/full material, full automation, unattended operation.

Fast tray switching (time 5-8s)

The equipment is set with temporary storage, which can cache 1-2PCS fixture to automatically adjust production line.

The production capacity is up to 2500~4500/UPH ( bar code reading direction affects the UPH)

The suction head is equipped with rotation function to meet all kinds of IC rotation requirements before packaging.

Automatic taping system:

Range: 32~104mm, heat-seal, film adhesive;

Control system: Servo motor control tape drive; Both sides of the sealing cylinder independently control the tape with hot pressure packaging;

Electrostatic precipitator: The dust generated by SMT production line can be removed twice and collected by vacuum dust collection system to ensure the delivery quality of tape products after packaging.

Intelligent System interaction: DP510H supports AOI detection of material picking/braid, and it can also scan laser label information of IC to provide full-process inspection for products. The production information can interact with MES in real time.

PGMES: Standard MES interface (order number, NG/OK number, running status).

One-key setting: Built-in standard template data (one-key setting parameters).

Auxiliary function: Report abnormal causes and provide solutions when alerting.

Device monitoring: Monitor and respond to device status (warning and adjusting parameters when the reject rate is high).

Maintenance: Remote service, Debugging; Maintenance reminders, Replacement reminders.