Maintenance automation equipment plays a crucial role in ensuring the smooth operation of various industries, from manufacturing to healthcare. These machines are designed to automate routine maintenance tasks, such as equipment inspections, repairs, and replacements, to improve efficiency and reduce downtime. The production process of maintenance automation equipment involves several key steps, from design and prototyping to manufacturing and testing. In this article, we will explore the mainstream production process of maintenance automation equipment in detail.

The first step in the production process of maintenance automation equipment is the design and prototyping phase. This involves creating a detailed blueprint of the equipment, including its dimensions, materials, and functionality. Designers use computer-aided design (CAD) software to create 3D models of the equipment, which allows them to visualize how it will look and function in real life.

Once the design is finalized, a prototype of the equipment is created using rapid prototyping techniques, such as 3D printing. This allows engineers to test the functionality of the equipment and make any necessary adjustments before moving on to the manufacturing phase.

Manufacturing

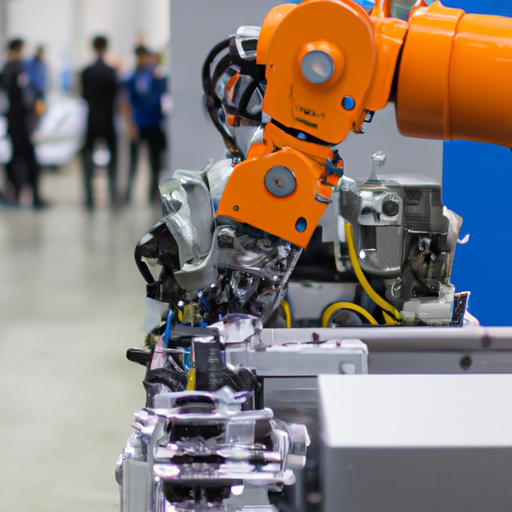

After the design and prototyping phase is complete, the next step in the production process is manufacturing. This involves sourcing the necessary materials and components, such as motors, sensors, and actuators, and assembling them into the final product. The manufacturing process can vary depending on the complexity of the equipment, but typically involves several key steps:

1. Assembly: The components of the equipment are assembled according to the design specifications. This may involve soldering, welding, or fastening the parts together using screws or bolts.

2. Wiring: Electrical components, such as sensors and actuators, are wired together to ensure they function properly. This may involve connecting wires to a control panel or circuit board.

3. Programming: The equipment is programmed to perform the desired maintenance tasks, such as conducting inspections, making repairs, or replacing parts. This may involve writing code for a microcontroller or PLC (programmable logic controller).

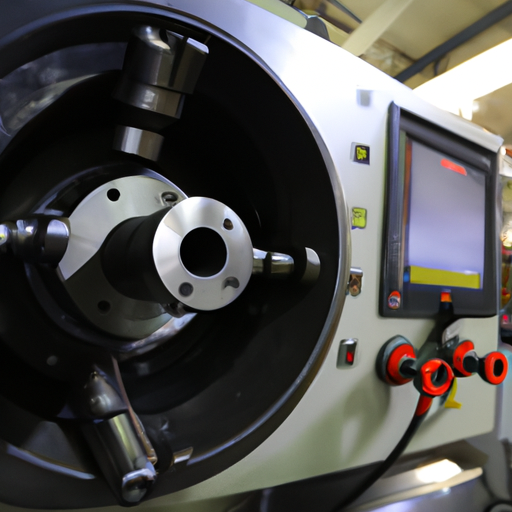

4. Testing: Once the equipment is assembled and programmed, it undergoes rigorous testing to ensure it functions correctly. This may involve running simulations, conducting performance tests, and troubleshooting any issues that arise.

Quality Control

Quality control is an essential part of the production process for maintenance automation equipment. This involves inspecting the equipment at various stages of production to ensure it meets the required standards of quality and performance. Quality control measures may include:

1. Inspections: Inspectors visually inspect the equipment for any defects or imperfections, such as misaligned components or loose connections.

2. Testing: The equipment is tested under real-world conditions to ensure it functions as intended. This may involve running it through a series of maintenance tasks to simulate its performance in a live environment.

3. Certification: Once the equipment has passed all quality control checks, it may be certified by a third-party organization to ensure it meets industry standards and regulations.

Packaging and Shipping

Once the maintenance automation equipment has been manufactured and passed quality control checks, it is packaged and prepared for shipping to customers. Packaging is an important step in the production process, as it protects the equipment from damage during transit and ensures it arrives in good condition. The equipment may be packaged in boxes, crates, or pallets, depending on its size and weight.

After the equipment is packaged, it is shipped to customers using various transportation methods, such as trucks, trains, or airplanes. The shipping process may involve coordinating with logistics companies to ensure the equipment arrives at its destination on time and in good condition.

Conclusion

The production process of maintenance automation equipment is a complex and multi-step process that involves design, prototyping, manufacturing, quality control, and shipping. By following these steps carefully and diligently, manufacturers can ensure the equipment meets the required standards of quality and performance. Maintenance automation equipment plays a vital role in improving efficiency and reducing downtime in various industries, making it an essential tool for modern businesses.